Concept

The space industry demands cost effective solar cells with high performance and improved radiation hardness. This can generally be achieved by a combination of several measures: Developing novel cell structures with more than 3-junctions for optimal utilization of the sun spectrum, the choice of appropriate cell materials for radiation hardness and a manufacturing route optimized for cost efficiency.

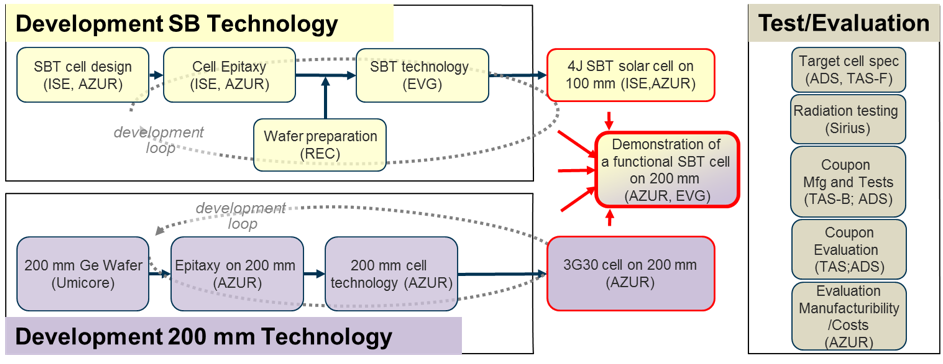

Our approach in RadHard is to develop a sophisticated 4-junction solar cell which makes use of extremely radiation hard InP materials. Implementation of this novel device shall be achieved by combining established, state-of-the-art solar cell technologies (epitaxy, device manufacturing processes) and semiconductor bonding technology which has not been involved in the value chain before. This new manufacturing concept enables avoiding fundamental limitations for practical realization of multi-junction solar cells regarding inherent link between physical properties of preferred semiconductor materials (namely, dependence of the band gap on the lattice constant) and technical feasibility to combine them in one device in only one epitaxy process as it is done for current products. Commercial viability is achievable by solar cell epitaxy and semiconductor bonding on cost effective ultra large 200 mm Ge substrates to be addressed in the project as well.

Motivation

Next generation solar cell product for European space industry: The RadHard´s 4-junction SBT solar cell targets a BOL efficiency of 35% and an EOL efficiency of 31% and thus will surpass the state of the art values by 5% absolute. This will be a similar breakthrough in space solar power as the switch from Si based cells to III/V multi-junction cells in the late 1990s. There, the BOL limiting efficiency of Si cells of about 18% was surpassed by an equal margin of the first dual junction solar cells with 23% efficiency.

The wafer bonding is an industrial technology that will not only allow volume production but also provide the same potential for future efficiency growth (e.g. with 5-junction cell architecture) as the lattice matched growth technology of the previous technology curve. This is recognised by European Space Agency ESA and directly reflected in its Roadmap for Solar Generators and Solar Cells that is approved by IPC Technology Harmonisation Advisory Group (ESA Reference: ESA/IPC/THAG(2015)05, iss.4-2, 15.9.2016).

Realization of the 4-junction SBT cell on ultra large Ge wafers will enable industrial competitiveness. Firstly, Ge wafers are >10x less expensive than InP wafers (InP would allow a better epitaxy process), secondly, 200 mm InP wafer are not available. As illustration, compared to 100 mm, a 200 mm wafer provides an up to 4x larger functional device area which can be processed within one production batch.

Due to specific focus on cost efficiency and radiation hardness, basically all missions will benefit from the development in RadHard, from commercial telecom missions to very exceptional scientific missions. All these missions business focus of European satellite primes Airbus D&S and Thales.